Your maintenance manager enters Monday's operations meeting with alarming statistics: "We spent $2.3 million on scheduled preventive maintenance last quarter, but still experienced 47 hours of unplanned downtime from equipment failures." You examine the maintenance reports—thousands of hours devoted to time-based servicing—yet critical assets failed between scheduled intervals, causing production losses exceeding $850,000. Without understanding the fundamental differences between predictive vs preventive maintenance strategies, you are potentially over-maintaining healthy equipment while missing actual failure warning signs.

This dilemma confronts manufacturing facilities nationwide as operations teams struggle to balance maintenance costs with equipment reliability. Traditional preventive maintenance follows rigid schedules regardless of actual equipment condition, while predictive maintenance monitors real-time asset health to optimize intervention timing. The average industrial facility spends 60-70% of maintenance resources on preventive activities, but predictive approaches can reduce total maintenance costs by 25-35% while improving equipment availability by 30-45%.

Facilities implementing strategic predictive vs preventive maintenance combinations achieve 50-65% reductions in unplanned downtime while extending asset life by 20-40% compared to traditional time-based maintenance approaches. The transformation requires understanding each strategy's strengths, limitations, and optimal applications for different equipment types and operating environments.

Ready to optimize your maintenance strategy and eliminate $850,000 in preventable equipment failures?

Stop guessing when equipment needs attention. Discover how predictive maintenance identifies problems 30-90 days before failure while preventive maintenance ensures systematic care for critical assets.

Understanding Predictive vs Preventive Maintenance Fundamentals

Effective maintenance strategy selection requires understanding the fundamental differences between predictive and preventive maintenance approaches. Preventive maintenance operates on predetermined schedules based on manufacturer recommendations or historical data, performing routine services regardless of actual equipment condition. Predictive maintenance continuously monitors asset health through sensors and data analysis, triggering maintenance activities only when performance indicators suggest developing problems.

Preventive maintenance provides predictable scheduling and systematic equipment care, making it ideal for critical assets requiring guaranteed reliability. However, this approach often results in over-maintenance of healthy equipment while potentially missing rapidly developing faults between scheduled intervals. Preventive maintenance typically accounts for 80-85% of total maintenance activities in traditional manufacturing facilities.

Preventive Maintenance Characteristics

Time-based servicing following manufacturer schedules. Provides systematic equipment care and predictable maintenance budgets but may result in unnecessary interventions on healthy assets.

Predictive Maintenance Features

Condition-based interventions triggered by real-time monitoring. Optimizes maintenance timing and reduces unnecessary work but requires technology investment and specialized skills.

Hybrid Maintenance Strategy

Combines predictive monitoring with preventive scheduling. Maximizes asset reliability while controlling costs through intelligent maintenance timing and resource allocation.

Asset-Specific Applications

Different maintenance strategies for various equipment types. Critical assets benefit from predictive monitoring while routine components may require only preventive maintenance.

Predictive maintenance leverages vibration analysis, thermal imaging, oil analysis, and performance monitoring to assess actual equipment condition. This approach typically reduces maintenance costs by 25-35% while improving asset availability, but requires initial technology investment and staff training. The most successful facilities implement hybrid strategies combining predictive monitoring for critical assets with preventive maintenance for routine components.

Predictive vs Preventive Maintenance Cost Analysis

Understanding the financial implications of predictive vs preventive maintenance strategies enables better resource allocation and ROI optimization. Initial investment requirements, ongoing operational costs, and potential savings vary significantly between approaches, requiring comprehensive analysis to determine optimal strategy selection for different equipment categories and operational priorities.

| Maintenance Strategy | Initial Investment | Annual Operating Cost | Downtime Reduction | Cost Savings Potential |

|---|---|---|---|---|

| Preventive Maintenance | $50,000 - $150,000 | $800,000 - $2M | 20-30% | 10-20% vs reactive |

| Predictive Maintenance | $200,000 - $500,000 | $600,000 - $1.3M | 35-50% | 25-35% vs preventive |

| Hybrid Strategy | $300,000 - $700,000 | $650,000 - $1.4M | 45-65% | 40-55% vs traditional |

| Reactive Maintenance | $25,000 - $75,000 | $1.2M - $3M | 0-10% | Baseline comparison |

Labor allocation differs significantly between predictive vs preventive maintenance strategies. Preventive maintenance requires scheduled technician availability for routine services, while predictive maintenance demands specialized skills for data analysis and condition interpretation. Hybrid strategies optimize labor utilization by combining predictive insights with preventive scheduling, typically improving technician productivity by 30-40%.

Equipment-Specific Maintenance Strategy Selection

Strategic maintenance planning requires matching appropriate strategies to specific equipment types, operating conditions, and criticality levels. Different assets respond better to predictive vs preventive maintenance approaches based on failure modes, monitoring feasibility, and replacement costs. Understanding these relationships enables optimal strategy deployment that maximizes reliability while controlling maintenance expenses.

Maintenance Strategy Selection Process

Equipment-Specific Strategy Applications

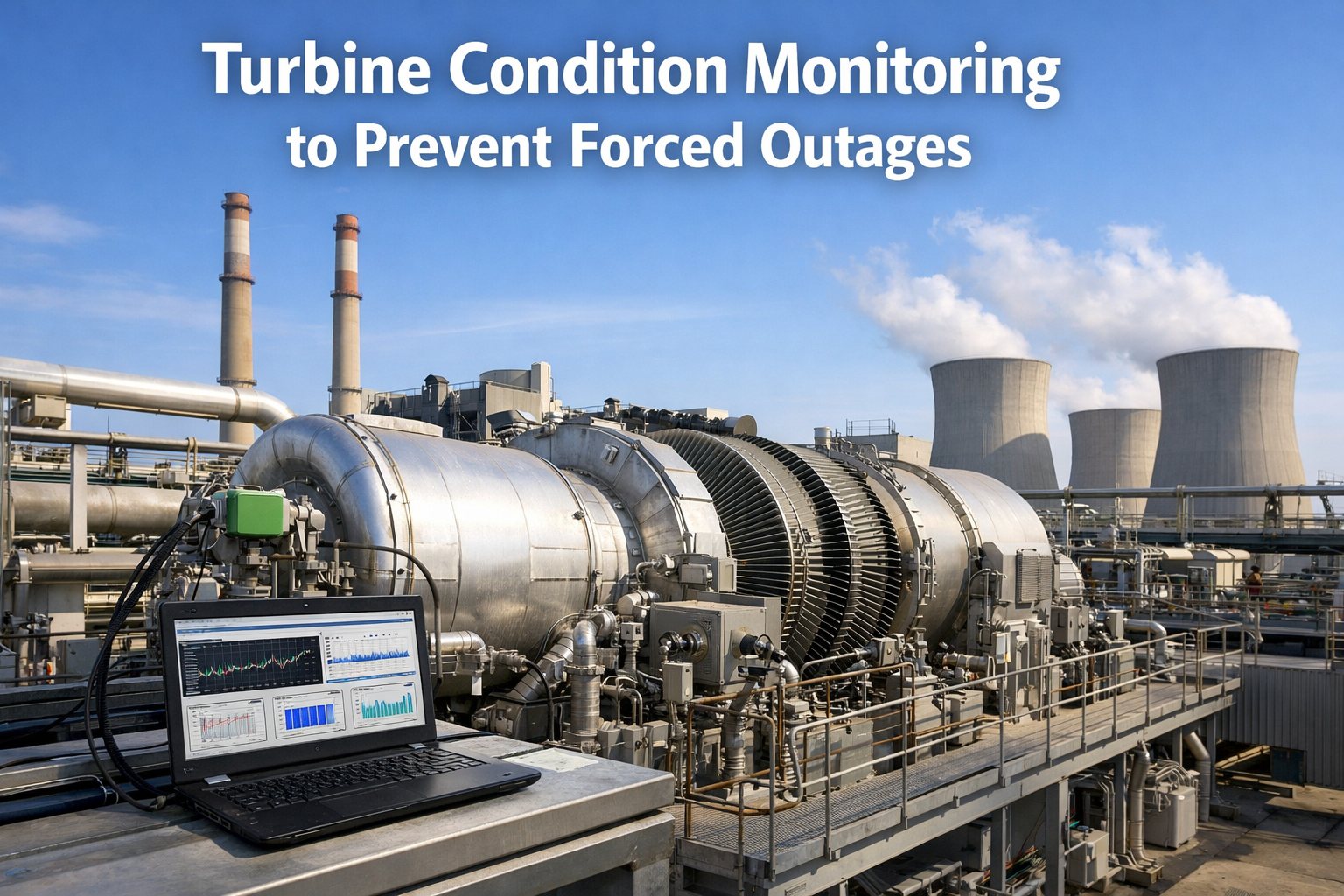

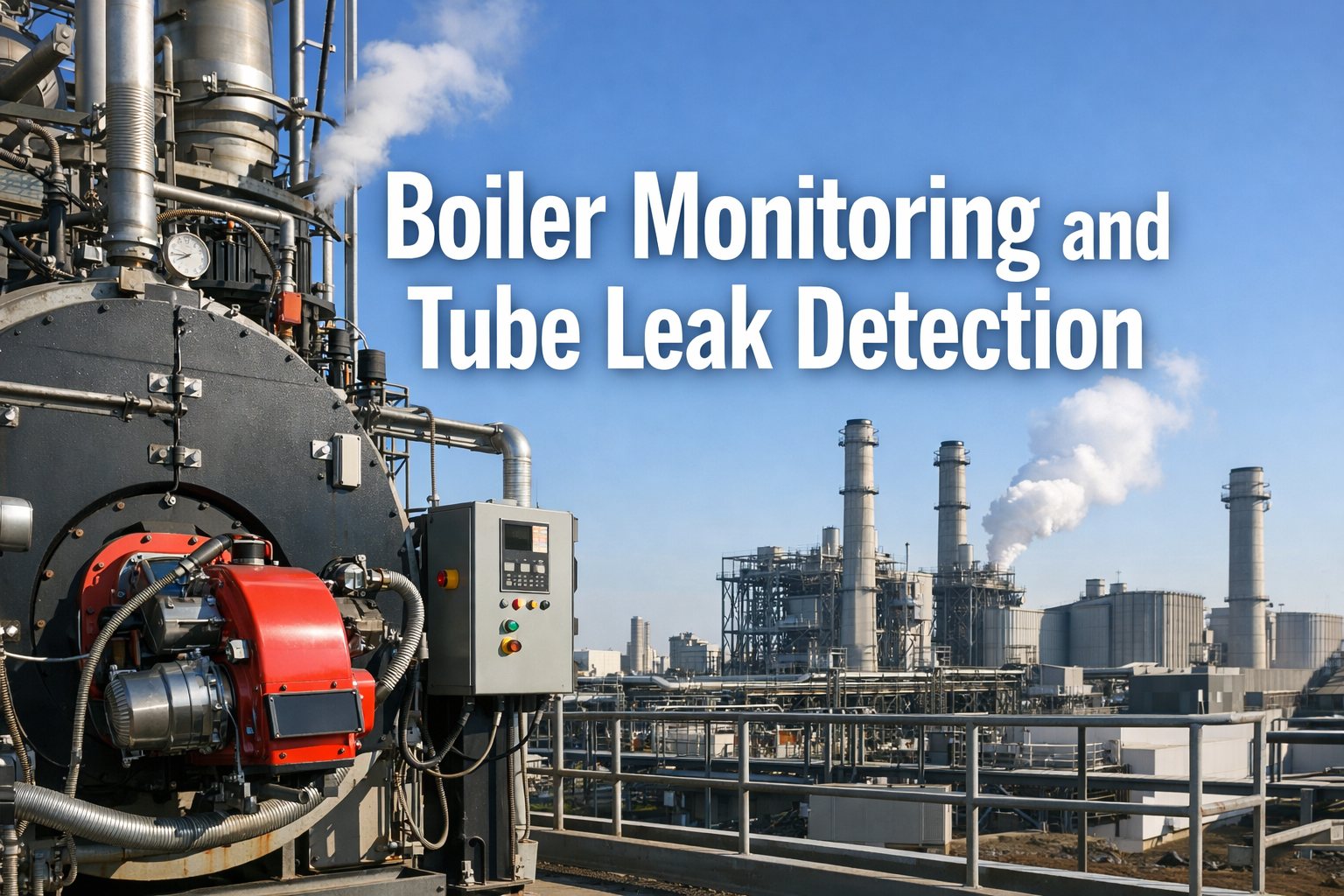

- Critical rotating equipment: Deploy predictive monitoring for bearing analysis and vibration trending

- Electrical systems: Implement thermal imaging and ultrasonic monitoring for arc fault detection

- HVAC equipment: Combine predictive monitoring with seasonal preventive maintenance schedules

- Conveyors and material handling: Use predictive belt monitoring with preventive lubrication programs

- Process instrumentation: Apply preventive calibration with predictive drift analysis

- Safety systems: Maintain strict preventive schedules with predictive component monitoring

Asset complexity and replacement costs significantly influence optimal maintenance strategy selection. High-value equipment with complex failure modes typically benefits from predictive monitoring, while routine components may require only preventive maintenance. The most successful facilities achieve 60-75% of maintenance value through strategic matching of maintenance approaches to equipment characteristics and operational requirements.

Implementation Best Practices and Technology Integration

Successful predictive vs preventive maintenance implementation requires systematic planning, technology integration, and organizational change management. The most effective deployments phase implementation across asset categories while building internal capabilities for sustained program success. Technology selection, staff training, and performance measurement systems determine long-term program effectiveness and ROI achievement.

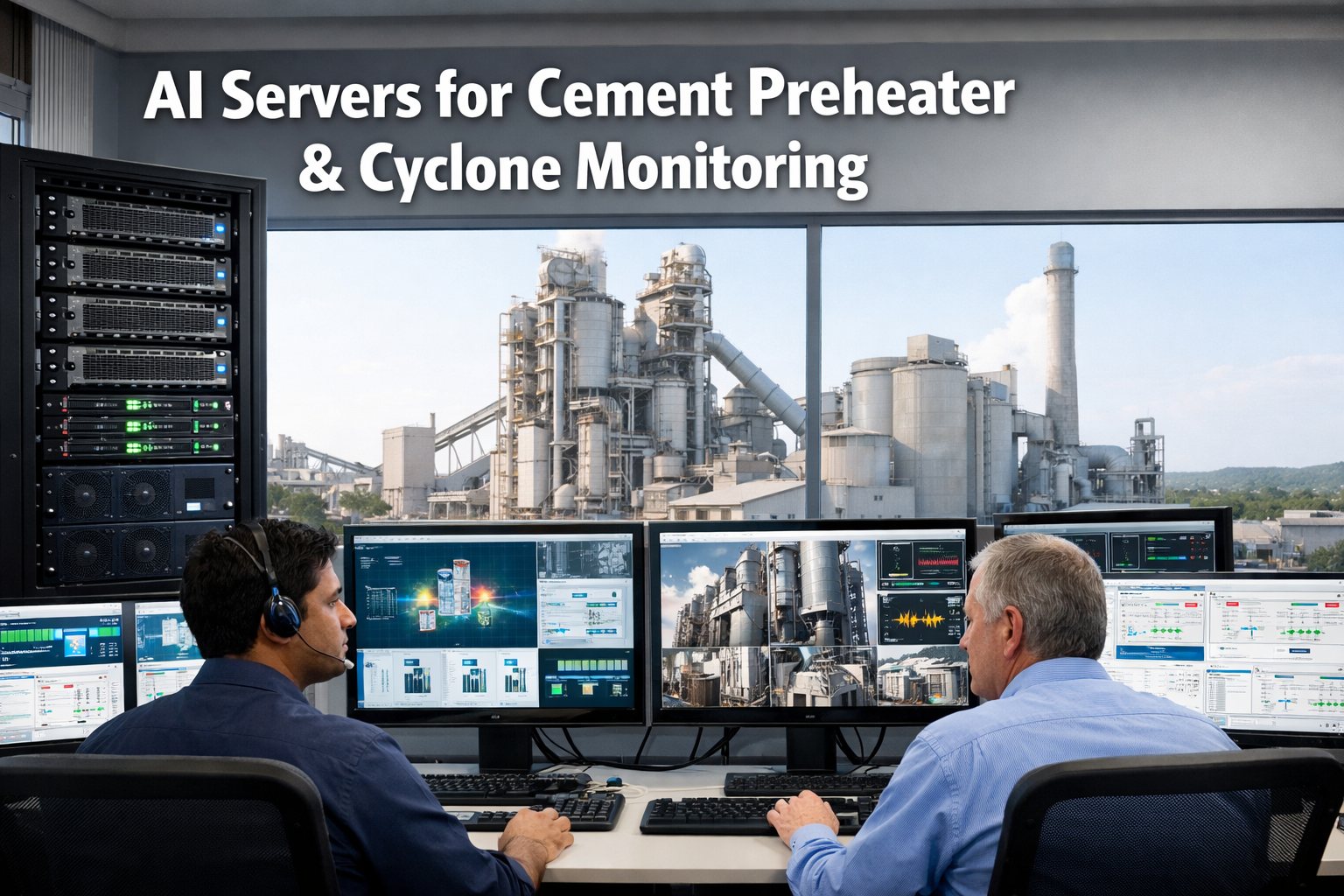

2025 Maintenance Technology Trends

- AI-powered analytics enabling automatic condition pattern recognition and failure prediction

- Wireless sensor networks providing cost-effective monitoring for previously uneconomical assets

- Digital twin integration combining predictive monitoring with virtual asset performance modeling

- Mobile platforms delivering real-time condition data and maintenance recommendations to technicians

- Cloud-based analytics enabling remote monitoring and expert consultation capabilities

- Automated work order generation triggered by predictive maintenance algorithms

Integration complexity varies significantly between predictive vs preventive maintenance systems. Preventive maintenance typically requires scheduling systems and inventory management, while predictive maintenance demands sensor networks, data analytics platforms, and condition monitoring expertise. Hybrid approaches require seamless integration between both systems, often achieved through modern CMMS platforms supporting multiple maintenance strategies.

Training requirements differ substantially between maintenance approaches. Preventive maintenance emphasizes procedural consistency and scheduling adherence, while predictive maintenance requires condition analysis skills and technology proficiency. Most successful implementations invest 20-30% of total project resources in training and change management to ensure sustained adoption and program effectiveness.

Conclusion

Predictive vs preventive maintenance strategies each offer distinct advantages for modern manufacturing operations, with optimal results achieved through strategic combination based on equipment criticality, operating conditions, and organizational capabilities. Understanding these approaches enables facilities to reduce maintenance costs by 25-55% while improving asset availability by 30-65% through intelligent intervention timing and resource optimization.

The fundamental differences between predictive and preventive maintenance reveal that neither strategy alone addresses all maintenance requirements effectively. Preventive maintenance provides systematic equipment care and predictable scheduling, while predictive maintenance optimizes intervention timing through real-time condition monitoring. Hybrid strategies combining both approaches typically deliver 40-60% better results than single-strategy implementations.

Financial analysis demonstrates that predictive maintenance requires higher initial investment but delivers greater long-term savings through optimized maintenance timing and reduced emergency repairs. Equipment-specific strategy selection maximizes program effectiveness by matching maintenance approaches to asset characteristics and operational requirements, with successful implementations achieving 45-60% better performance than generic approaches.

Implementation success requires comprehensive planning combining technology selection, organizational development, and performance measurement systems. Modern maintenance technologies enable previously uneconomical monitoring applications while mobile platforms and cloud analytics democratize predictive maintenance capabilities for facilities of all sizes.

The 2025 maintenance environment rewards organizations implementing intelligent combinations of predictive and preventive strategies while penalizing those relying solely on traditional approaches. Success requires balancing proven preventive maintenance practices with emerging predictive technologies that optimize intervention timing and asset performance.

Ready to implement the optimal predictive vs preventive maintenance strategy that reduces costs by 25-55% while improving equipment reliability?

Every day with suboptimal maintenance strategy costs your facility thousands in unnecessary repairs and lost production. The technology and expertise exist today to optimize your maintenance approach—implement intelligent maintenance strategies before your next costly equipment failure.