Your cement kiln has been running 24/7 for 287 days straight. The bearing temperatures are slightly elevated—nothing alarming yet. The vibration readings show a subtle shift that your operators haven't noticed. But here's what predictive analytics would tell you: those bearings have approximately 23 days of useful life remaining. A kiln failure at this point would cost your plant $300,000 per day in lost production. The emergency repair? Another $150,000 minimum. Predictive maintenance exists precisely to prevent this nightmare—transforming subtle equipment signals into scheduled repairs that happen on your timeline, not the equipment's.

Why Cement Plants Can't Afford Reactive Maintenance

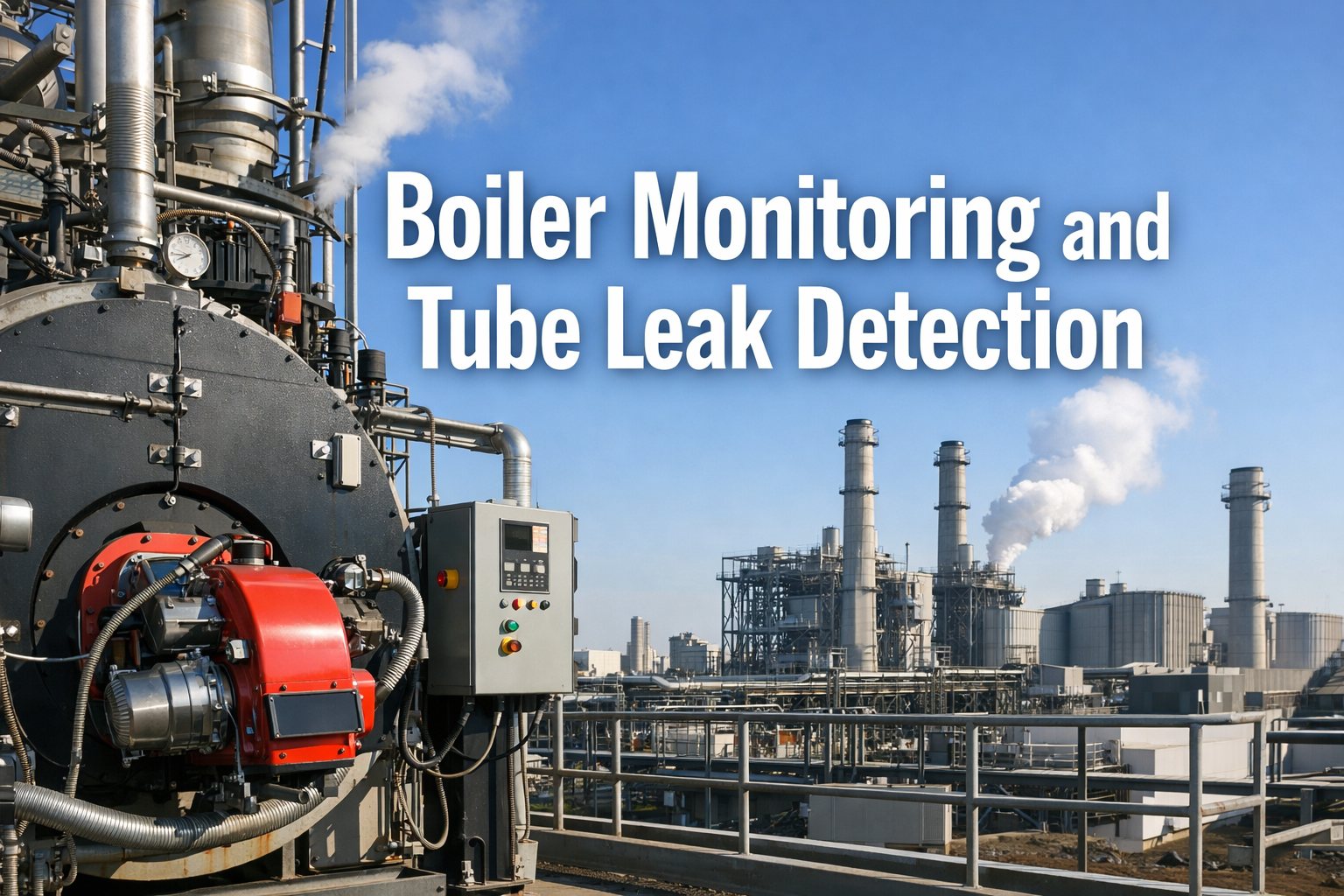

Cement production is one of the most equipment-intensive manufacturing processes in existence. Your rotary kiln operates at temperatures exceeding 1,500°C. Your vertical roller mills grind raw materials under extreme mechanical stress. Your crushers, conveyors, fans, and gearboxes work continuously in dust-heavy, high-vibration environments.

The cement industry has historically operated with over 30% downtime—raw mills and finish mills running at just 70-80% efficiency. Plants that sign up for OXmaint's free trial are changing those numbers dramatically, achieving uptime rates that were previously considered impossible through data-driven maintenance decisions.

How Predictive Maintenance Technology Works

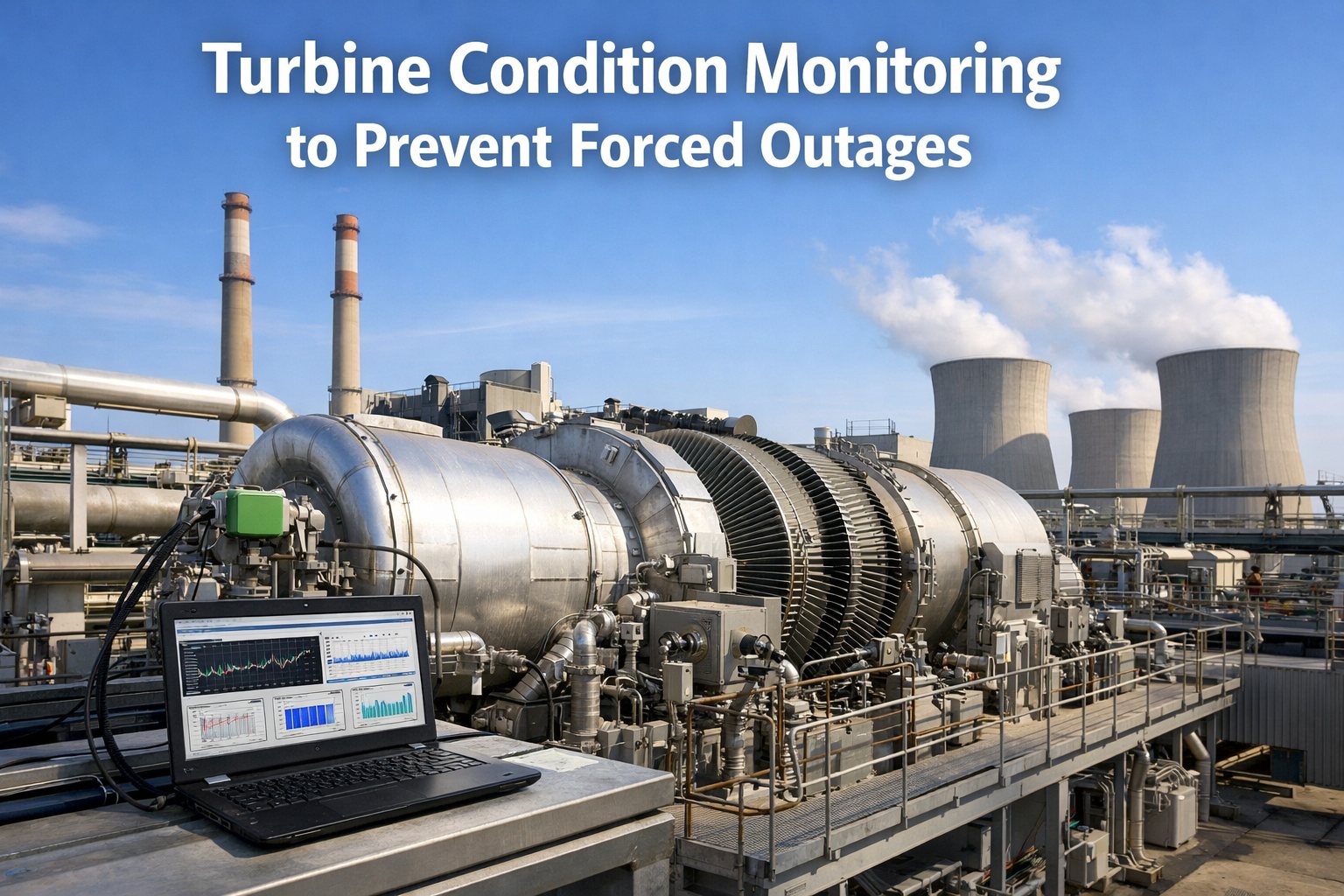

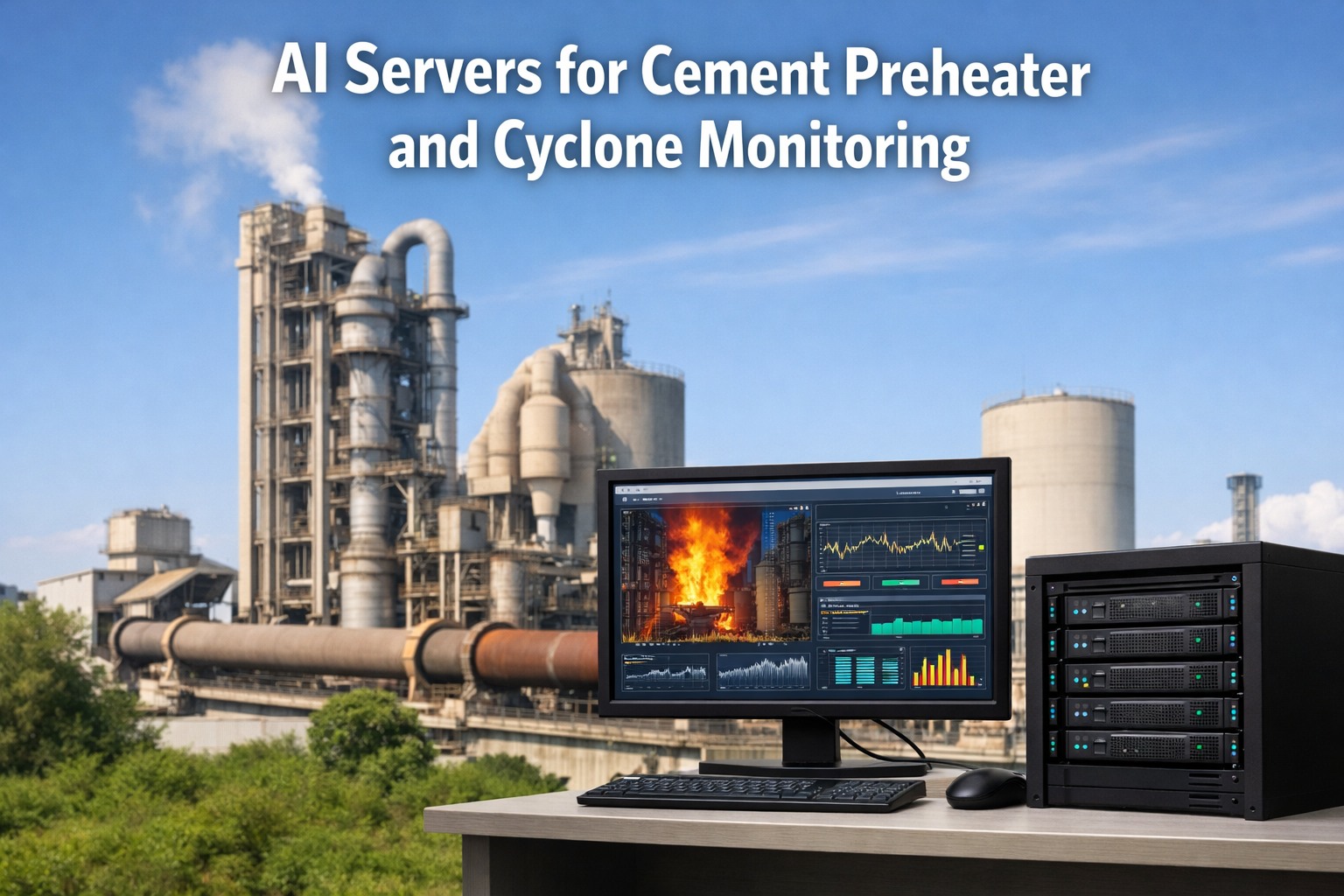

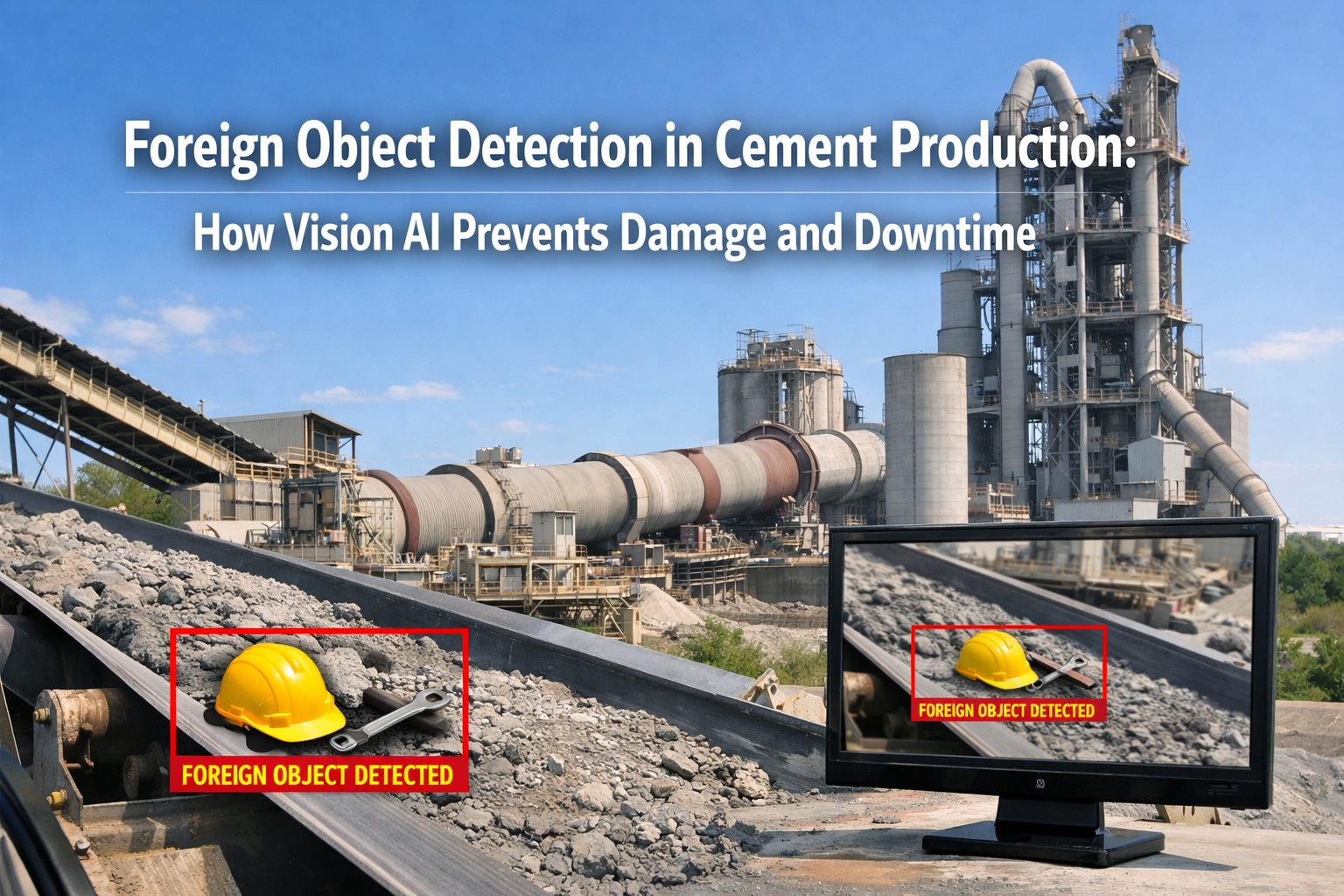

Modern predictive maintenance combines multiple monitoring technologies to create a complete picture of equipment health. Vibration sensors detect bearing wear and misalignment. Temperature sensors track overheating. Current analysis identifies electrical anomalies. All this data feeds into AI algorithms trained on thousands of cement-specific failure patterns.

Your maintenance team receives actionable alerts weeks before failures occur. Plants that book a demo to see this workflow discover how automatic work order generation, technician assignment and parts ordering transforms maintenance from reactive firefighting into strategic planning.

The ROI Numbers That Matter

According to the U.S. Department of Energy, predictive maintenance saves 8-12% over preventive maintenance and up to 40% over reactive maintenance. For cement plants, this means measurable returns within months—often from a single prevented emergency.

Leading cement manufacturers are already seeing these results. Holcim has deployed predictive maintenance across 45 plants globally, monitoring 3,000 sensors on critical equipment. Plants that create a free OXmaint account gain the visibility needed to replicate these results at any scale.

Expert Perspective on Early Detection

"In the cement industry, where even an hour of unplanned downtime can translate into $100,000 in lost revenue, focused application of predictive maintenance could mean savings of millions annually. Facilities investing in early detection aren't just avoiding breakdowns—they're transforming how maintenance operates."

The cement plants succeeding with predictive maintenance have connected monitoring sensors to a CMMS platform that automates response workflows. Ready to explore what this looks like? Schedule your personalized demo and our team will identify which equipment to monitor first based on your plant's needs.

Getting Started: Your First 90 Days

Implementing predictive maintenance doesn't require replacing your entire infrastructure. Modern wireless sensors install in hours, connect to cloud platforms automatically, and begin establishing baseline patterns immediately. Start with your most critical equipment—kiln, primary mills, and single-point-of-failure machines.

Ready to move from reactive chaos to predictive intelligence? Start your free OXmaint trial today and begin capturing the data that prevents failures before they happen.