Manufacturing facilities across the United States are facing unprecedented pressure to reduce operational costs while meeting increasingly stringent environmental regulations. With energy expenses typically accounting for 15-25% of total manufacturing costs, smart power management isn't just an environmental initiative—it's a critical business strategy that directly impacts your bottom line.

The good news? Leading manufacturers are already proving that energy efficiency and profitability go hand in hand. Companies implementing comprehensive energy management systems are seeing average cost reductions of 20-30% within the first year, while simultaneously reducing their carbon footprint and improving equipment reliability.

Did you know? The average manufacturing facility wastes 30% of its energy consumption through inefficient equipment operation, poor scheduling, and lack of real-time monitoring. This represents thousands of dollars in unnecessary costs every month.

Understanding Your Energy Consumption Baseline

Before implementing any energy efficiency measures, you need a clear picture of where and how your facility consumes power. Most manufacturers are surprised to discover that their assumptions about energy usage don't match reality.

Start by conducting a comprehensive energy audit that examines:

- Peak demand periods and their correlation with production schedules

- Equipment-specific power consumption during different operational modes

- Standby power usage during non-production hours

- Power quality issues that may be increasing consumption

- Compressed air, lighting, and HVAC system efficiency

Modern energy monitoring systems can provide granular, real-time data that reveals patterns invisible to traditional monthly utility bills. This data becomes the foundation for all subsequent optimization efforts.

Ready to discover your facility's hidden energy savings potential?

Book a DemoSmart Equipment Scheduling and Load Management

One of the most impactful strategies for reducing energy costs involves optimizing when and how equipment operates. Time-of-use electricity rates mean that running the same equipment at different times can result in dramatically different costs.

Peak Demand Shifting

Many manufacturers can reduce their electricity bills by 15-20% simply by shifting non-critical operations away from peak demand periods. This might involve:

- Running energy-intensive processes during off-peak hours

- Utilizing thermal mass for heating and cooling load shifting

- Implementing smart staging for equipment startup sequences

- Coordinating production schedules with utility rate structures

Equipment Right-Sizing and Variable Speed Drives

Oversized equipment running at partial load is one of the biggest energy wasters in manufacturing. Variable frequency drives (VFDs) can reduce energy consumption by 20-50% for motors, pumps, and fans by matching output to actual demand rather than running at constant full capacity.

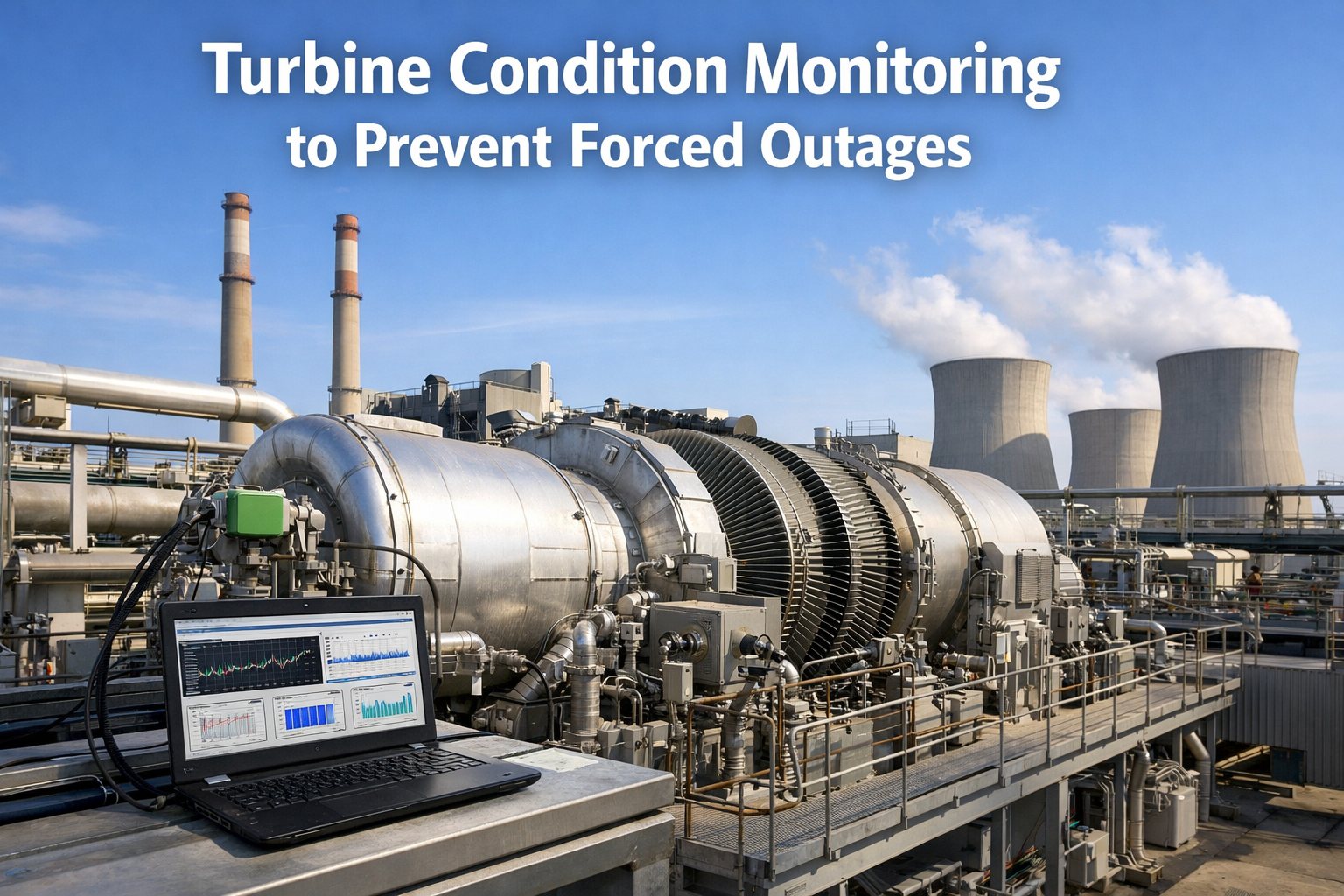

Advanced Power Monitoring and Analytics

Real-time power monitoring has evolved from simple measurement to sophisticated analytics that can predict equipment failures, optimize maintenance schedules, and automatically adjust operations for maximum efficiency.

Modern systems integrate multiple data sources to provide actionable insights:

- Power quality analysis to identify and correct inefficiencies

- Predictive analytics for maintenance scheduling optimization

- Automated load shedding during peak demand periods

- Integration with weather forecasts for HVAC optimization

- Real-time cost tracking and budget alerts

Case Study: A mid-sized automotive parts manufacturer reduced energy costs by 28% in six months by implementing smart monitoring and automated load management, saving over $180,000 annually while improving equipment reliability by 35%.

Sustainable Practices That Drive Profitability

Sustainability initiatives often provide the fastest return on investment when properly implemented. Beyond the obvious environmental benefits, these practices typically offer immediate cost savings and long-term operational advantages.

LED Lighting and Smart Controls

Industrial LED retrofits typically pay for themselves within 18-24 months through energy savings alone. When combined with occupancy sensors and daylight harvesting controls, savings can exceed 70% of lighting-related energy costs.

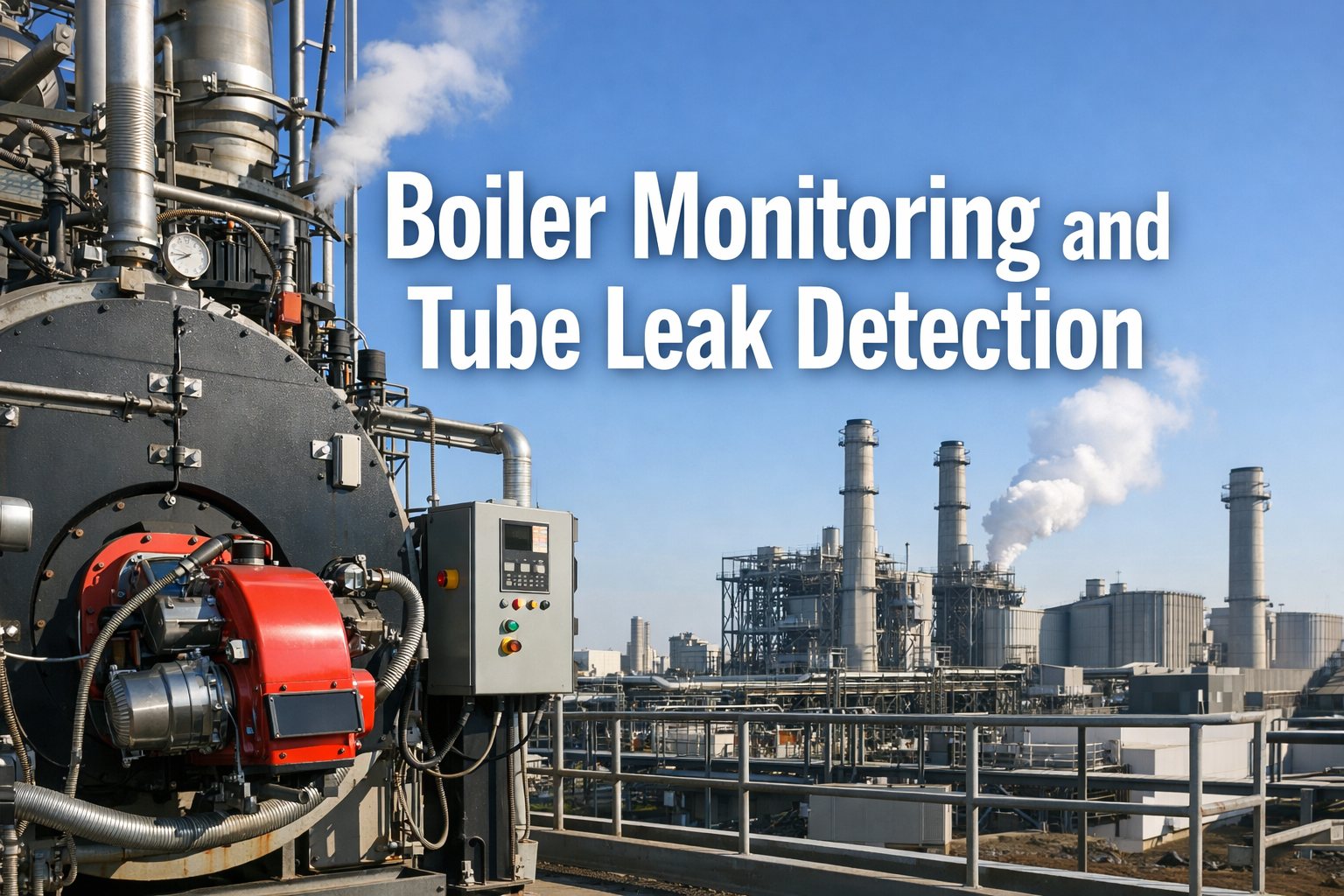

Compressed Air System Optimization

Compressed air is often called the "fourth utility" in manufacturing, yet most systems operate at 20-30% efficiency. Implementing leak detection programs, right-sizing compressors, and optimizing pressure settings can reduce compressed air energy consumption by 30-50%.

Heat Recovery and Waste Energy Utilization

Many manufacturing processes generate significant waste heat that can be captured and repurposed. Heat recovery systems can often provide 15-25% energy savings with payback periods of 2-4 years.

Transform your workshop into an energy-efficient powerhouse today!

Getting StartedTechnology Integration and Automation

The most successful energy management programs leverage technology to automate routine decisions and optimize performance continuously. This includes integrating energy management with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms.

Key technologies driving energy efficiency include:

- IoT sensors for real-time equipment monitoring

- Machine learning algorithms for predictive optimization

- Automated demand response systems

- Mobile dashboards for facility managers

- Integration with renewable energy sources

The goal is creating a self-optimizing system that continuously improves efficiency without requiring constant manual intervention from your team.

Conclusion: Your Path to Energy Excellence

Energy-efficient workshop management isn't just about reducing costs—it's about creating a competitive advantage that positions your facility for long-term success. Companies that implement comprehensive energy management strategies today will be better positioned to handle future energy price volatility, regulatory changes, and customer sustainability requirements.

The key to success lies in taking a systematic approach: start with accurate measurement, implement proven technologies, and continuously optimize based on real data. With the right strategy and tools, most manufacturers can achieve 20-30% energy cost reductions while improving operational reliability and environmental performance.

The question isn't whether you can afford to implement energy efficiency measures—it's whether you can afford not to. Your competitors are already moving in this direction, and the early adopters will gain the greatest advantages.

Don't let another month of unnecessary energy costs slip by. Start your energy efficiency journey today.

Getting StartedBook a Demo

Frequently Asked Questions

What is the typical ROI timeline for energy efficiency investments in manufacturing?

Most energy efficiency improvements in manufacturing facilities show positive ROI within 12-36 months. Simple measures like LED lighting upgrades often pay for themselves in 18-24 months, while comprehensive energy management systems typically achieve full payback in 2-4 years. The key is prioritizing quick wins first, then using those savings to fund larger initiatives.

How much can smart power management actually reduce my energy costs?

Industry data shows that manufacturers implementing comprehensive smart power management strategies typically reduce energy costs by 20-30% in the first year. Some facilities achieve even higher savings—up to 40-50%—depending on their starting efficiency level and the scope of improvements implemented. The average mid-sized manufacturing facility saves $150,000-$300,000 annually.

Do I need to shut down production to implement energy efficiency measures?

Most energy efficiency improvements can be implemented with minimal or no production downtime. Monitoring systems, software upgrades, and many equipment modifications can be installed during scheduled maintenance windows or shift changes. Major equipment replacements may require brief shutdowns, but these are typically planned during already-scheduled maintenance periods to minimize impact.

What's the difference between energy monitoring and energy management?

Energy monitoring involves collecting and displaying energy consumption data, while energy management uses that data to automatically optimize operations. Monitoring tells you what's happening; management takes action to improve efficiency. A complete system includes both real-time monitoring and automated controls that respond to changing conditions without manual intervention.

Are there government incentives available for manufacturing energy efficiency projects?

Yes, multiple federal, state, and utility incentive programs exist for manufacturing energy efficiency. These include federal tax credits, state rebate programs, and utility demand-side management incentives. Programs vary by location and can cover 20-50% of project costs. It's worth consulting with an energy efficiency specialist to identify all available incentives for your specific situation and location.